Fully automatic pharmaceutical packaging machine

Fully automatic pharmaceutical packaging machine , The equipment can produce 3000-15000 pieces per hour, and the price range is 5000-200,000 US dollars. Its core advantage is that it can ensure the sterilization and zero pollution of the drug packaging process, while achieving high-precision metering of ±0.1%

Sealing method: heat sealing/pulse sealing

Applicable dosage forms: tablets, capsules, etc.

Packaging form: blister/bag, etc.

Packaging speed: 100-300 packs/minute

Material requirements: 304 stainless steel body

Precision error: ≤±0.5%

What is Fully automatic pharmaceutical packaging machine?

Fully automatic pharmaceutical packaging machine is a high-precision intelligent equipment designed for the pharmaceutical industry. It strictly follows GMP standards and works in coordination with PLC control system and sensors to achieve full process automation of drug metering, mixing, filling, sealing, labeling, etc. The equipment is suitable for common pharmaceutical packaging materials such as composite film, PE film, and aluminum foil film. The equipment can produce 3000-15000 pieces per hour, and the price range is 5000-200,000 US dollars. Its core advantage is that it can ensure the sterilization and zero pollution of the drug packaging process, while achieving high-precision metering of ±0.1%, greatly improving drug production efficiency and quality stability, and reducing the risks brought by manual intervention.

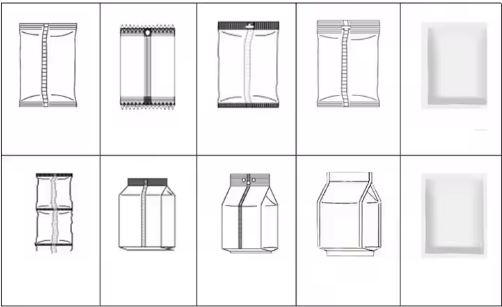

Packaging forms of Fully automatic pharmaceutical packaging machine

Fully automatic pharmaceutical packaging machine supports a variety of packaging forms such as flat bags, strip bags, back-sealed bags, special-shaped bags, blisters, etc. The molds and molding structures can be customized as needed to meet the packaging needs of different dosage forms of drugs. Common packaging forms include:

Aluminum-plastic blisters: used for tablets and capsules, the material is PVC+aluminum foil, moisture-proof and anti-oxidation, suitable for long-term storage and export packaging.

Four-side seal packaging: suitable for small-dose drugs such as powders and granules, the bag size is 30×40mm to 100×140mm, the seal is neat, and the metering accuracy is high.

Strip bag packaging: suitable for granules, vitamin powders, etc., the bag width is 17–50mm, supports multi-channel joint packaging, and the packaging is light and easy to carry.

Bottle sealing: used for liquid preparations such as oral liquids and syrups, the filling volume is 10–500ml, the speed is 30–100 bottles/minute, and it integrates filling, capping, sealing, and labeling, which meets GMP requirements.

Technical parameters of Fully automatic pharmaceutical packaging machine

Fully automatic pharmaceutical packaging machine has different configurations according to different models. The following are the general configuration reference parameters: speed 30-120 packs/minute, accuracy ±0.51%, sealing width 10-300mm, PLC control, touch screen operation, suitable for tablets, powders, liquids, etc.

Packaging speed: 30-120 packs/minute.

Measuring accuracy: ±0.5-1%.

Applicable packaging materials: PET/AL/PE, paper-plastic composite film, etc.

Seal width: adjustable range is 10-300mm.

Power requirements: AC 220V/380V, 50Hz.

Control system: PLC control + touch screen operation interface.

Machine size: about 3200×850×1600mm (customizable).

Applicable dosage forms: tablets, capsules, granules, powders, liquids, etc.

| Model | Equipment Configuration |

| Packaging speed | 30-120 packs/minute |

| Measuring accuracy | ±0.5-1% |

| Applicable packaging materials | PET/AL/PE, paper-plastic composite film, etc. |

| Seal width | adjustable range is 10-300mm |

| Power requirements | AC 220V/380V, 50Hz |

| Control system | PLC control + touch screen operation interface |

| Machine size | about 3200×850×1600mm (customizable) |

| Applicable dosage forms | tablets, capsules, granules, powders, liquids, etc. |

Price range distribution of Fully automatic pharmaceutical packaging machine

According to the application scenario and configuration level, the price of Fully automatic pharmaceutical packaging machine can be roughly divided into the following categories:

Laboratory-grade small equipment, suitable for drug research and development and small-batch trial production, priced at about US$5000-20,000;

Basic production equipment, meeting conventional tablet and capsule packaging, with an output of 5000-8000 per hour , priced at $20,000-80,000;

High-end intelligent models, with high-speed packaging, online detection, and data traceability functions, are suitable for large-scale pharmaceutical production lines, and the price is as high as $80,000-200,000.

Common equipment types of fully automatic pharmaceutical packaging machine

Fully automatic pharmaceutical packaging machine can be subdivided into a variety of special equipment according to the packaging form and material type, suitable for efficient packaging of drugs in different dosage forms.

Classification by packaging form:

Blister packaging machine: used for tablets and capsules, through forming, feeding, heat sealing, punching and other processes to complete the sealed packaging, suitable for PVC+aluminum foil or aluminum-aluminum materials, running speed of 30-60 plates/minute, suitable for mass production.

Cartoning machine: automatically puts medicine plates, instructions, and desiccant into paper boxes, integrating box opening, filling, coding, and box sealing, suitable for blisters, strip bags and bottled drugs.

Liquid filling and packaging machine: suitable for liquid dosage forms such as syrup and oral liquid, using piston pump or peristaltic pump for high-precision filling, filling range 10-500ml, integrated capping, sealing and labeling functions.

Granule packaging machine: used for granules and powders, equipped with spiral or vibration feeding system, supports back seal, strip bag, four-side seal and other bag types, speed up to 40-100 bags/minute, suitable for multi-channel continuous packaging.

Powder packaging machine: suitable for Chinese medicine powder and granules, using spiral metering, supporting dust removal and weighing feedback system to ensure cleanliness and accuracy.

Strip bag packaging machine: for portable small-dose products (such as granules, nutritional powder, etc.), supports 1-10 strips of joint packaging, small bag width, easy to tear and carry.

Classification by degree of automation:

Semi-automatic model: requires manual assistance in feeding or operation, suitable for small batch production and testing, low cost and flexible operation.

Fully automatic model: realizes automatic feeding, packaging, sealing, labeling and testing, with functions such as intelligent adjustment and fault self-detection, high production efficiency, stable quality, and meets GMP standards.